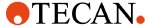

Assemble and manage results from preformulation material characterization studies, including thermal data, SEM, and XRPD.

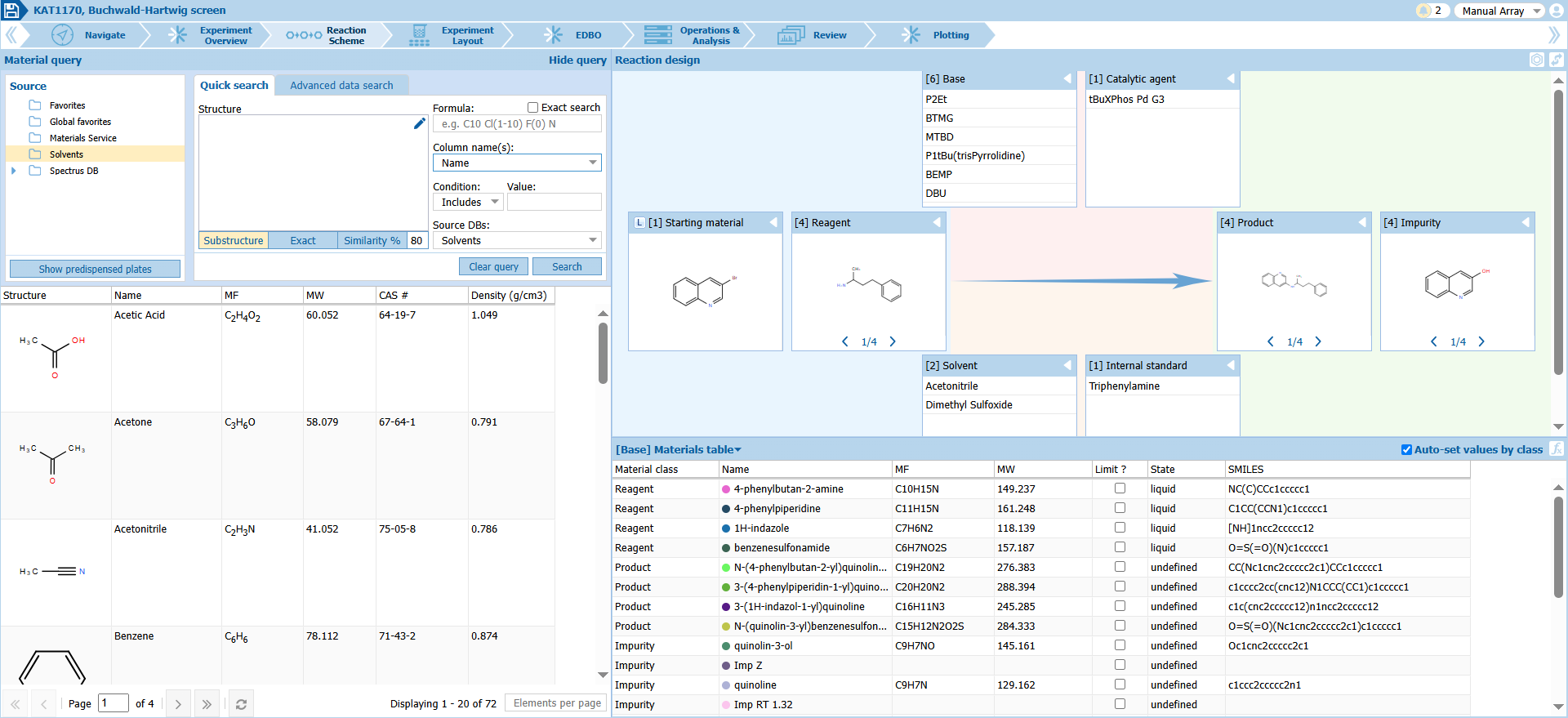

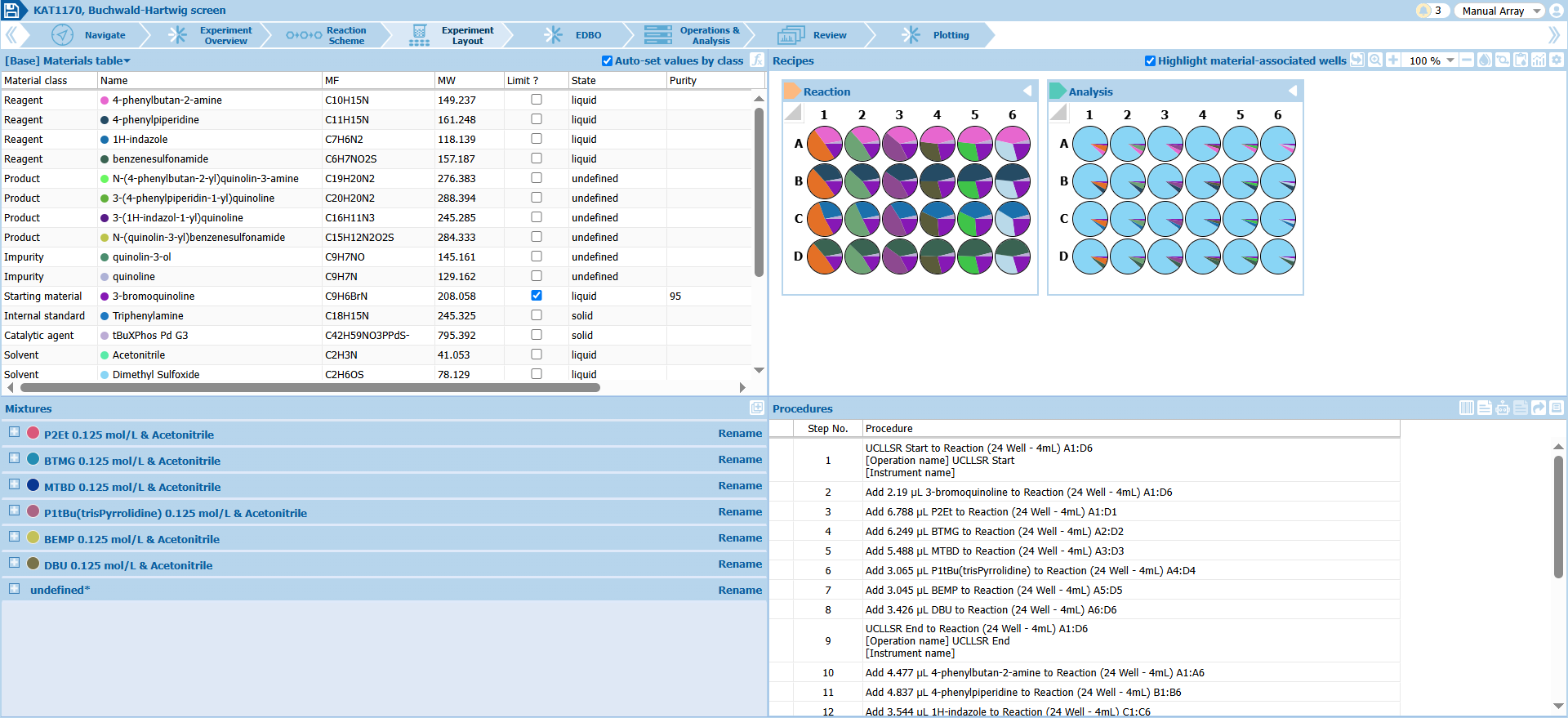

Intuitively design high throughput, parallel chemistry, and process optimization experiments. Drag-and-drop materials from all your material sources into the reaction scheme.

Effortlessly plan high throughput experiments and generate machine readable instruction files for robot execution.

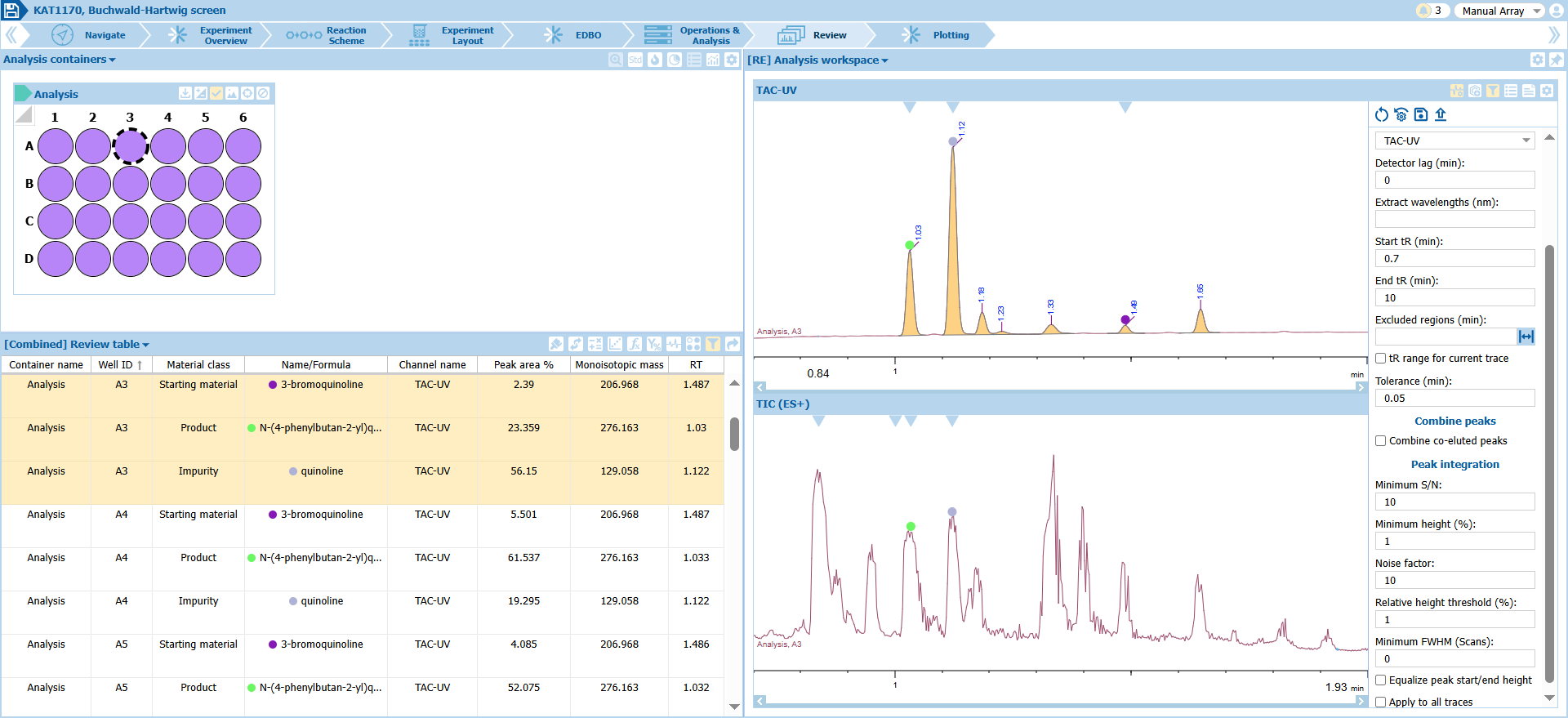

Process and analyze all your LC/UV/MS data, automatically linked to each sample, in the same interface.

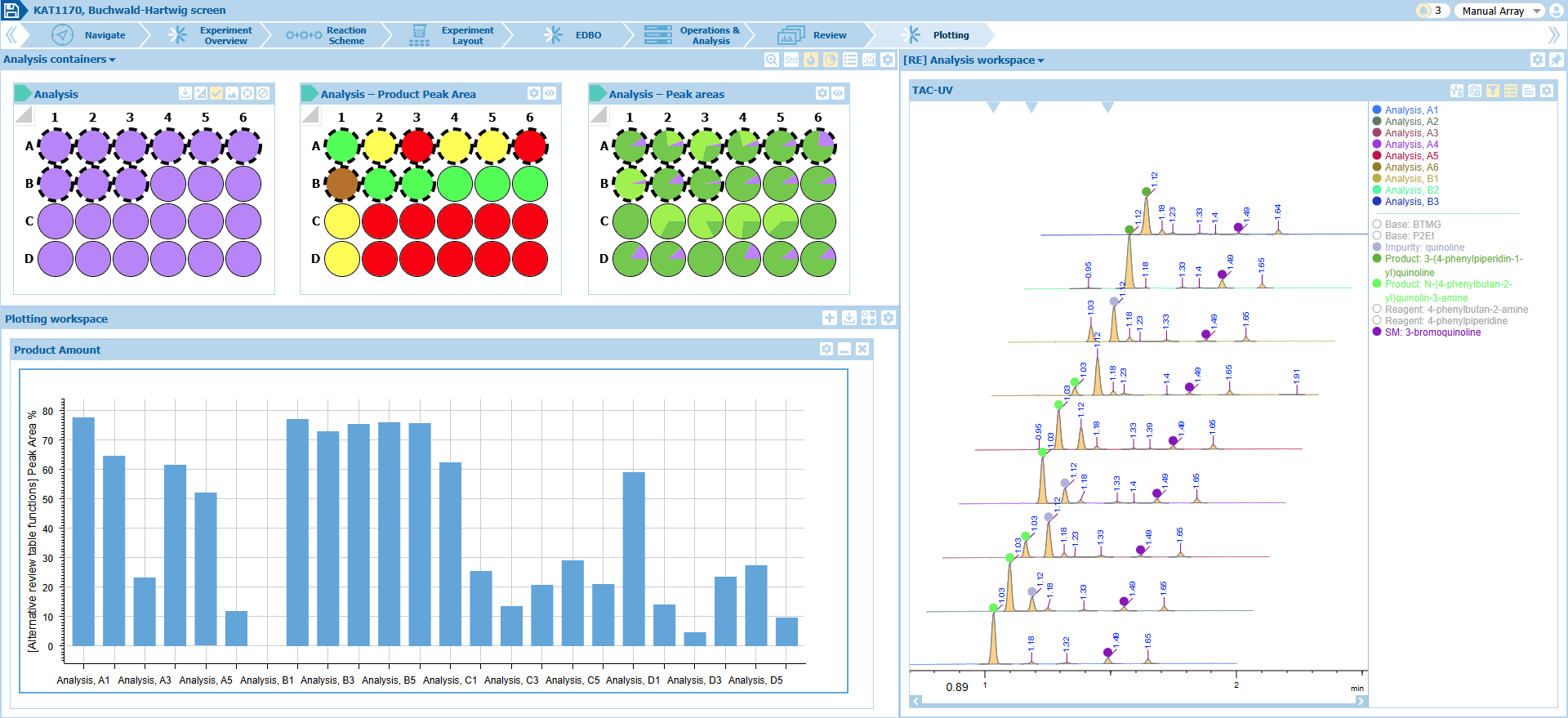

Visualize reaction optimization results in series and generate heat maps, pie charts, and plots to make faster decisions.

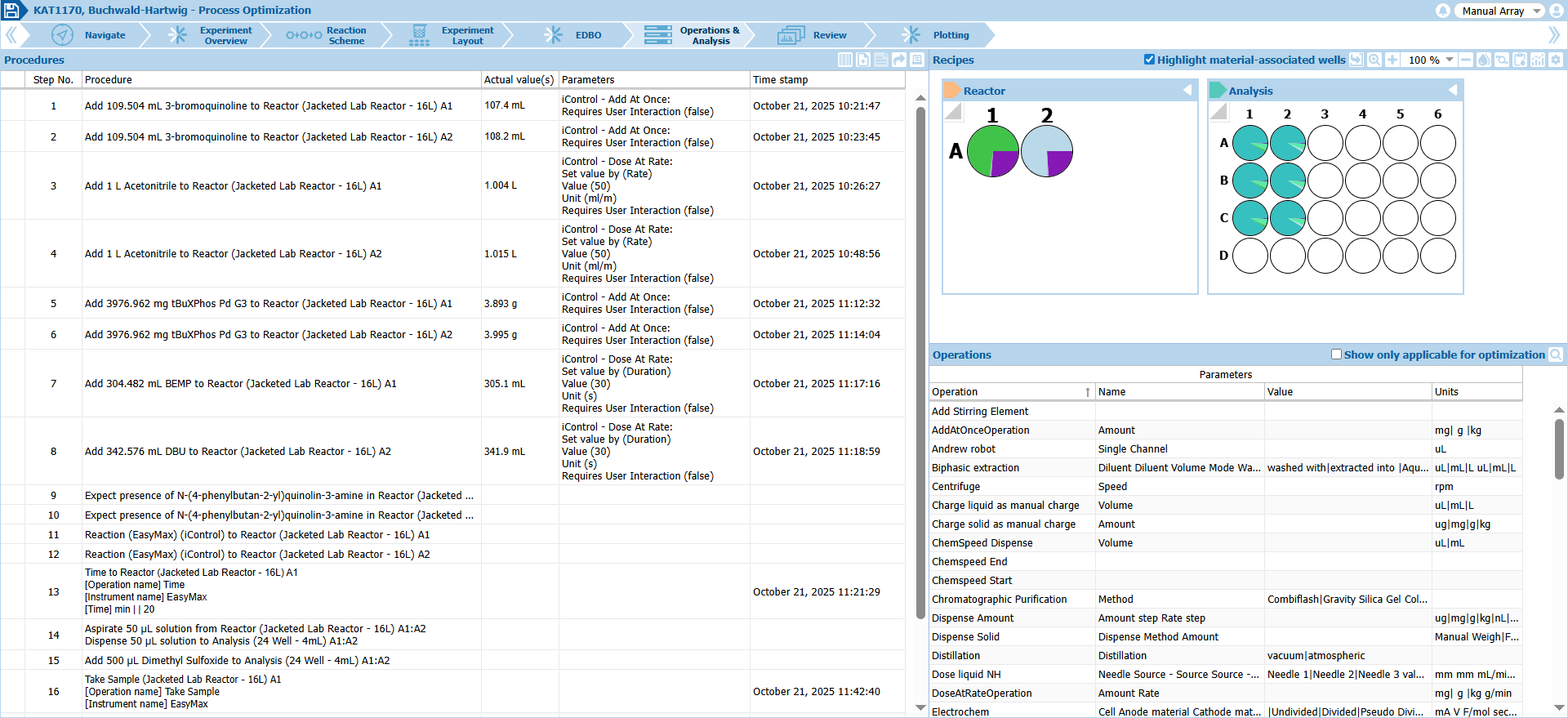

Effortlessly plan process optimization/scale-up experiments using jacketed lab reactors and set up sample analysis.

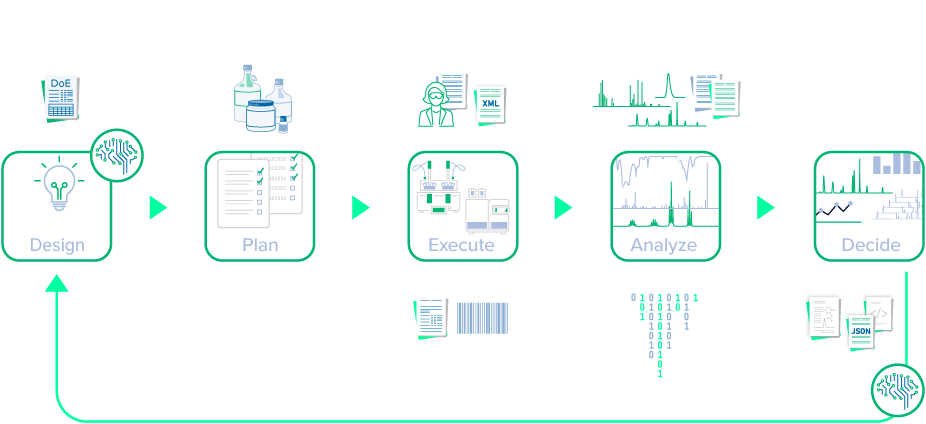

Design

Design  Plan

Plan  Execute

Execute  Analyze

Analyze  Decide

Decide