September 25, 2025

by Baljit Bains, Marketing Communications Specialist, ACD/Labs

Making Deformulation More Efficient in Pharma and Biopharma

Deformulation, the process of breaking down a drug product into its individual chemical components, is a critical step in pharmaceutical and biopharmaceutical research. Whether it’s for competitive intelligence, troubleshooting a tricky formulation, ensuring quality, or meeting regulatory requirements, deformulation helps scientists understand exactly what a product contains and in what proportions.

But anyone who has been involved in a deformulation project knows it’s not always easy or straightforward.

- It’s complex: Formulations often contain a mix of active pharmaceutical ingredients (APIs), excipients, and stabilizers, with different physical and chemical properties.

- It’s time-consuming: Traditional workflows are often manual, requiring repetitive data handling, juggling multiple instruments, and tedious comparisons between datasets.

- It’s frustrating: When results are scattered across different systems or require lots of manual interpretation, delays are inevitable.

Traditional vs. Modern Deformulation Approaches

The traditional deformulation approach usually involves identifying peaks of interest from chromatograms and performing database searches. This often means spending long hours at the bench, juggling multiple instruments and manually piecing together results from different systems. It’s a slow, resource-heavy process that demands expertise many teams no longer have as group sizes shrink, and responsibilities grow.

Modern approaches turn that around by pairing advanced LC/MS and GC/MS tools with smart software and automation. Instead of chasing data across spreadsheets and reports, scientists can centralize results, visualize and compare components side by side, and make faster, more confident decisions. The result? Deformulation that’s quicker, more reliable, and far less of a headache.

Centralize LC/MS and GC/MS Data

One of the biggest roadblocks in deformulation is scattered data, with results split between vendor software, spreadsheets, and siloed systems. It makes pulling everything together slow and frustrating. By bringing all your LC/MS and GC/MS data into one connected platform, you can line up chromatograms and spectra side by side, search across past projects, and even reprocess raw data without rerunning instruments.

The payoff? Huge time savings and access to the data in a consistent format, that everyone on the team can actually use.

Automate Routine Analysis

With today’s analytical software, routine tasks such as peak picking, component identification, and spectral matching don’t have to be manual anymore. By letting algorithms handle this repetitive work, you can:

- Cut down on tedious manual steps and analyst fatigue

- Get more consistent, reproducible results without subjective guesswork

- Free up scientist time to focus on meaningful, high-value analysis

Plus, automation makes early-stage screening faster, helping you decide quickly whether further work is necessary.

Maintain a Reusable Component Database

Over time, building a searchable library of known excipients, APIs, degradation products, and impurities can dramatically reduce identification time. Each new deformulation project adds to the collection, building a valuable resource that:

- Makes it faster to recognize components in future analyses

- Improves accuracy with curated, in-house data

- Supports knowledge retention even when team members change

Streamline Collaboration

When projects span multiple sites or teams, passing data around can slow everything down. With centralized databases (especially cloud-based platforms), scientists can:

- Share results in real time

- Add comments directly on spectra and chromatograms

- Leverage knowledge from databases

The result? Clearer communication, quicker progress, and fewer mistakes.

How Can We Help? Software Solutions for Deformulation

ACD/Labs helps deformulation scientists streamline complex workflows with tools like IntelliXtract 2.0 (our componentization algorithm) and Intelligent Component Recognition (IXCR), available within our expert MS and Chromatography software solutions. Designed to work across multiple instrument vendors and data formats, these platforms give analytical scientists the flexibility they need.

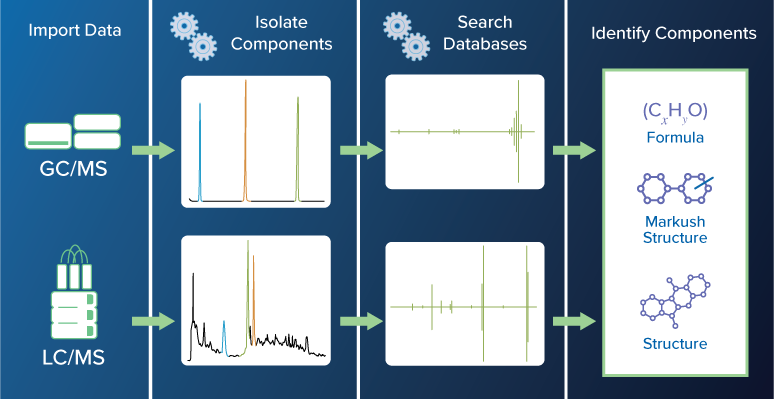

By automating key steps, our solutions reduce manual effort, improve efficiency, and help meet the growing demands of deformulation. They can separate chromatographic components, generate clean spectra, and search databases to suggest likely structures or formulas—in one integrated workflow.

Efficiency in Action

What once took hours can now be done in a fraction of the time, sometimes in just a minute. Thanks to the right tools, we have a quick, simple workflow:

- Component Identification: Specify and set options for component identification, including whether searching MS1 (GC/MS data) or MS2 (LC/MS data) spectra, how many hits, and what hit quality threshold you are interested in searching. Then let the IntelliXtract algorithm separate chromatographic components and generate pure component spectra, with annotations of the confirmatory and fragment ions, mass, and [M+H]+ depending on whether it is GC/MS or LC/MS data. This process is repeated for each component in your spectrum, and provides you with a table containing the mass spectra of all the components.

- Database Searching and Candidate Evaluation: Search public or in-house databases to compile a list of possible structural candidates, with results ranked by confidence scores, mass error, and hit quality. Use the IXCR tool to review hits with mirror plots that compare experimental and library spectra, complete with annotations for confirmatory and fragment ions. The hit quality index (HQI) helps you to gauge confidence in your results.

The Payoff

By embracing modern deformulation strategies, labs can shrink timelines by days, or even weeks—while gaining far more than just speed. Streamlined workflows mean greater reproducibility, cleaner data, and less manual effort, all of which drive smarter decisions and stronger R&D pipelines. In a field where time and accuracy are critical, making deformulation more efficient isn’t just a nice-to-have—it’s essential for staying competitive.